Focus on mold parts processing and production

86-136 8608 3098

86-137-1205-1128

Mr. Deng

Mobile

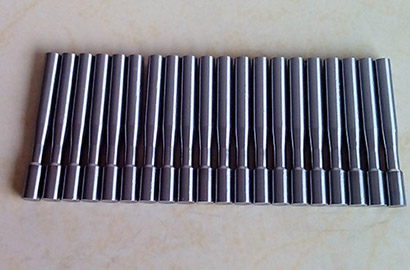

Tungsten carbide inserts, also known as tungsten steel inserts, are made from tungsten steel round rods. The main raw material is tungsten steel. Tungsten steel (hard alloy) has high hardness and wear resistance. Good strength and toughness, heat resistance, corrosion resistance and a series of excellent properties, especially its high hardness and wear resistance, generally installed on the stamping die for punching, so that the material is separated or plastically deformed. Get the parts you need.

Cemented carbide inserts have the characteristics of long service life, corrosion resistance and no rust due to high hardness, and are widely used in industrial machinery manufacturing and processing. It remains basically unchanged even at a temperature of 500°C, and still has a high hardness at 1000°C.

Cemented carbide, also known as tungsten steel, refers to a sintered composite material composed of at least one metal carbide.

Tungsten carbide, cobalt carbide, niobium carbide, and tantalum carbide are common components of tungsten steel. The grain size of the carbide component (or phase) is usually between 0.2-10 microns, and the carbide grains are bonded together using a metal binder. The binder usually refers to the metal cobalt (Co), but for some special applications, nickel (Ni), iron (Fe), or other metals and alloys can also be used.

Causes of wear

When the cemented carbide insert is plastically deformed in the mold cavity, it flows and slides along the surface of the cavity, causing severe friction between the surface of the cavity and the insert, which causes the insert to fail due to wear. Therefore, the wear resistance of the material is one of the most basic and important properties of the insert.

Hardness is the main factor affecting wear resistance. In general, the higher the hardness of the insert [1], the smaller the amount of wear and the better the wear resistance. Tungsten steel inserts are suitable for hardware and electromechanical processing industries. They are generally installed on stamping dies for punching to separate or plastically deform materials to obtain required parts.

Tungsten steel punches have the characteristics of long service life, corrosion resistance and no rust due to high hardness, and are widely used in industrial machinery manufacturing and processing. A thorough understanding of the grinding process of tungsten steel inserts is enough to recommend us how to choose a batch of high-precision cemented carbide inserts.

Reasons for choosing tungsten steel

The internal hardness is high, the toughness is particularly good, it is suitable for precision molds, and its service life can be significantly improved. The main raw material of the insert [2] is made of tungsten steel, so the reason for choosing it is because tungsten steel is a cemented carbide, also known as tungsten-cobalt alloy.

The hardness can reach 89~95HRA. Because of this, tungsten steel products are not easy to be worn, hard not afraid of annealing, but brittle.

About us

Profile Workshop Partner Case MessagesProducts center

News center

Company news Information ProblemContact US

Contact: Mr. Deng 86-13686083098Mobile website QR code